Tel: +44 (0)1373 463455

Email: info@keyford.co.uk

Keyford - One Supplier - Complete Solutions

Mechanical Engineering & Fabrication

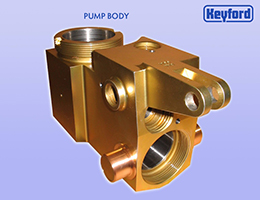

At Keyford our core business has always been Mechanical Engineering, with a vast experience in all areas from basic turning and milling through to high precision parts, complex assemblies and fabrications in a range of materials.

Over the many years we have been in business we have produced a diversity of items for the many sectors we have operated within. This has also meant that we have worked with a multitude of materials ranging from very simple Carbon Steels through to Tool Steel, Stainless Steel (including Inconel), Titanium, Aluminium Alloys, Copper, Brass, Composites (Tufnol, Orkot etc), Nylon, PTFE, Acetyl Copolymers and other plastics. In fact, we have probably worked with virtually any engineering material you care to name.

Our mechanical engineering capacities and capabilities are listed below.

MILLING - Manual, 2 axis & 3 Axis CNC. We have both turret and bed mills capable of producing accurate parts up to a maximum capacity of 1.5M x 0.6M x 0.7M

TURNING - Manual & CNC to a capacity of 0.76M diameter x 2.0M between centres.

LARGE TURNING - We have a very specialised capacity for large turning on our two Webster and Bennett Vertical Borers, being able to turn up to a diameter of 1.5M.

JIG BORING - Positional accuracy of 0.0025mm is achievable on our Jig Borer.

GRINDING - Surface grinding with a capacity of 250mm x 500mm x 200mm and cylindrical grinding to capacity of 250mm diameter x 685mm between centres.

EDM - Fanuc Tape Cut W2 Wire Eroder maximum workpiece capacity 450mm x 650mm x 300mm

PART IDENTIFICATION - A range of methods including Engraving, Vibro Percussion, Dot Impact, Stamping, Ink Marking and Stencilling. Capacities in all of these methods match our machining capacities.

FABRICATION - Capabilities in both MIG and TIG welding. Our approved welding engineers hold qualifications in carbon steel, stainless steel and aluminium alloys.

For a full list of plant and capacities, download our current CAPACITY LIST

COMPLETE CAPACITY SOLUTIONS - In addition to our own capacities, we also work closely with a range of specialist companies so that we can complete any project regardless of size or complexity.

SPECIAL PROCESSES - We also offer capabilities in wire/spark eroding, hardening, proof load testing, pressure testing, NDT, calibration, and finishing in a wide range of plating, painting and powder coating options through our approved supplier base.

We can source, arrange and manage all of these requirements and fully inspect all work so that you can have a hassle free, single point of contact for all of your needs.

All of the companies we work with hold the latest relevant approvals in their area of expertise, and have a proven track record of outstanding quality.